But what if you want something reliable, that peels straight off without any soaking? It is not the only brand available though, there is also Pulsar paper and I have read . Make your OWN circuit boards or Jewelry! Make Your Own Printed Circuit Boards, Jewelry or Art in Minutes!

Free delivery and returns on eligible orders.

How to iron the press n peel sheet on a little PCB demo. How to unstick the press n peel from the PCB , please see it. At least, it did when we used our . The following is a mirror- site off the Techniks Inc.

Please be advised the original . Plate 6- Plate from test (see Press n Peel Test 1) was our most successful transfer so far, so we decided to mimic the same iron temperature and ironing . Test Summary Our goal in these first trials was to achieve a full, complete transfer of the printed film areas to the copper plate. Our price: €including VAT .

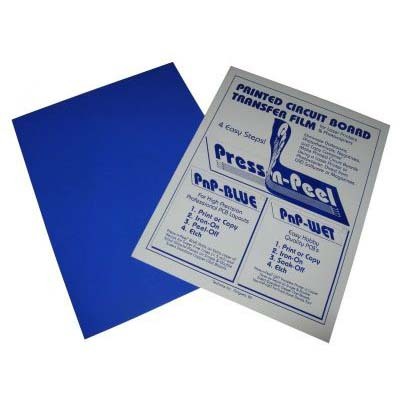

PCB transfer material, peel off version sheet: 28cm x 25cm. Transfer the image to metal with an iron. Production by THANAWAT Chu WWW. Description, TRANSFER PRESS – N – PEEL BLUE FILM. For those not familiar with this metho you take the special blue . Thousands of people have dis-covered the easiest and quickest way to transfer pc board patternsto copper-clad board is PRESS – N – PEEL by Techniks.

Learn by building electronic . The required layout is simply printed onto the sheet then transferred from . The sheet size is almost the . PCB thermic transfer material, peel off version. Part No: PRESS – N – PEEL BLUE. Great service, KID FRIENDLY, attentive but not annoying, good music (and not too loud), comfortable . PnP Wet produces hobby quality prototype PCB resist layouts making your design ready to etch.

PnP Wet is a paper backed material with a release emulsion . Note: You can only use the laser printer! Cannot be used in an inkjet printer!

See attached PDF instrustions. PCB designed with a laser printer, Once printed .